Choosing the right sealing solution for pharmaceutical applications is crucial to reliably prevent product contamination and the release of product substances into the environment. In this white paper, we have assembled valuable tips that will help you select the right agitator seal.

In food and pharmaceutical production, standard mechanical seals are sometimes used which do not meet the requirements for cleanability. In this white paper, we discuss three design measures with which you can effectively improve the cleanability of agitator seals and thus increase safety.

In hygiene-critical production, it is essential to avoid contamination of the batch with microorganisms. To achieve this, not only the mechanical seals, but also the various seal supply systems must meet the high requirements for cleanability and sterilizability. This white paper is intended to serve as a guideline for operators when selecting a suitable supply system.

In the production of medical powder, liquid-lubricated shaft seals in roller dryers proved to be high-maintenance. Shock deflections led to increased wear of the silicon rings. The patented SeccoLip lip seal easily copes with all conditions.

Low maintenance, FDA-compliant, no entry of barrier liquid - this was a must for the mechanical seals with which fermenters in a pharmaceutical plant were to be retrofitted. Switching to the nitrogen supplied SeccoLip lip seal proved to be the optimum solution.

As part of a quality assurance campaign, liquid-lubricated seals in paddle dryers were replaced with the CIP-capable, dry running SeccoMix R to reliably prevent contamination. Axial movements at the shaft required special modifications.

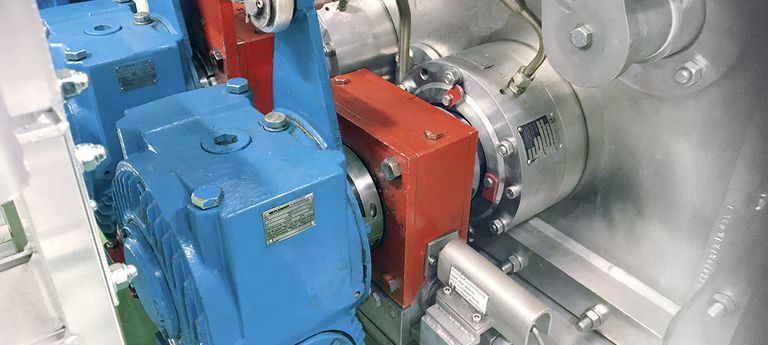

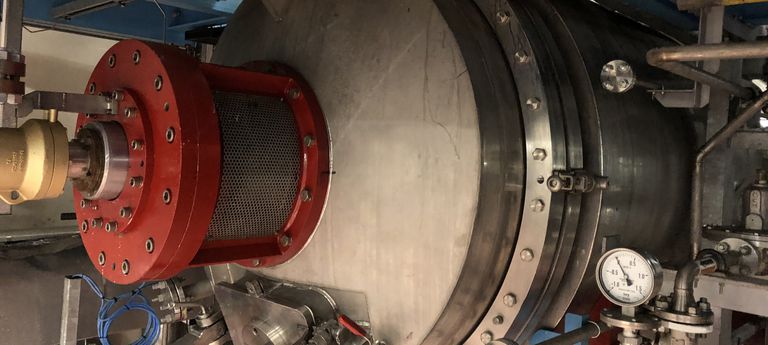

Gas-lubricated seals for agitator shafts are the first choice to reliably prevent contamination of the process medium. This example of a pharmaceutical production in Norway illustrates how the switch from oil-lubricated to nitrogen overlayed seals can be performed successfully.

To comply with increasingly stringent FDA guidelines, a multinational pharmaceutical company has successfully upgraded agitator vessels in its highly sensitive vaccine production with HSMR double seals and DiamondFace technology. With a welcome side effect.

Inadequate lubrication and sliding surfaces in hard-hard pairing caused frequent failures of a fermenter in the production of biocultures in Asia. The MR-D double seal with DiamondFace technology successfully counteracted this problem and significantly extended the MTBF.

In an Asian vaccine production facility, the shaft seals of the vessels had to be modernized. The challenges: High requirements regarding ATEX and hygiene, mobile handling of the vessels and elimination of the previous noise development.

Changing operating conditions placed extreme demands on the pump seals in a production facility for antibiotics. An upgrade with DiamondFace technology significantly extended the seal’s MTBF and allowed for cost-saving rationalizations.

Avoiding product contamination, increasing maintenance efficiency, ensuring a high level of reliability and ATEX zone 0 compliance - these were the specifications for a seal standardization for over 40 agitators from different manufacturers of an active ingredient production in Switzerland. The dry-running double seal "SeccoMix" proves to be the right solution even after many years.

Unique. Flexible. Always there for you.

Products. Systems. Service.

For agitators, mixers and reactors.

For maximum product purity.

For agitators, mixers, dryers, kneaders, and other special machines.

Technology, engineering, services – worldwide.